Position:

- Home

- scrap steel apron conveyor

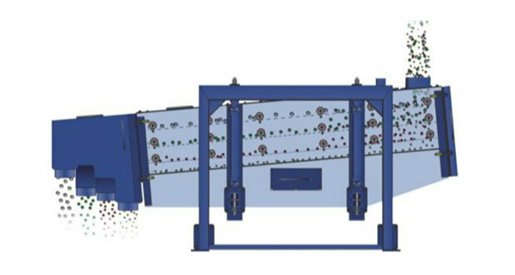

scrap steel apron conveyor

- Conveying Capacity:

150-500 t/h(customizable)

- Conveyor Width:

1200-3000mm

- Conveyor Length:

Up to 80 m (single unit)

- Material Type:

HMS scrap, heavy steel scrap

- Operating Conditions:

High impact, high dust, heavy load

Aimed at a prosperous growth in this domain, we are instrumental in

Product Overview

The Scrap Steel Apron Conveyor is a heavy-duty conveying system specifically engineered for the continuous handling and feeding of HMS scrap, bulky steel pieces, and irregular metal materials in harsh industrial environments.

Designed for steelmaking and scrap-recycling operations, this conveyor provides reliable performance under high impact, high abrasion, and dusty conditions. It is widely used as a primary feeding conveyor for Induction Furnaces (IF), Electric Arc Furnaces (EAF), and short-process steelmaking plants.

Key Features

Typical Applications

Typical Applications

- Scrap feeding system for Induction Furnaces (IF)and Electric Arc Furnaces (EAF)

- Scrap pre-charging systems for steel plants

- Scrap handling and conveying in recycling facilities

- Continuous feeding systems for short-process steelmaking lines

Main Technical Parameters

· |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Note: The mass conveying capacity is calculated according to the average material density of 0.45t /m³, and the compaction material can be preliminarily calculated according to the density of 1.1-1.4t/m³, depending on the density of the discharge material.

SINOHI Machinery

- Yidu city, Hubei province, China

- 24-hour online service

- Own factory processing